Furuichi Seicha

15 products

Introduction

A small, family-owned business, Furuichi Seicha manufacturers, blends, and sells tea from the beautiful tea fields of Kagoshima at its shop & cafe in the city of Minami-Kyushu.

OUR HISTORY & INFO

Founder Noboru Furuichi began the business by selling tea from his bicycle just after the end of World War II in 1948. At the time there were few tea finishing factories, and Noboru Furuichi wanted tea created better, so made the decision to create his own factory. The family business was incorporated in 1992, and President Shoji Furuichi continues his father's legacy in providing the best Japanese tea from Chiran Village, Kagoshima.

- President: Shoji Furuichi

- Location: 1296-1 Kawanabechō Nagata, Minamikyūshū-shi, Kagoshima-ken 897-0222

- Established: 1948, incorporated in 1992.

Shop & Cafe Ocha no Sawaki

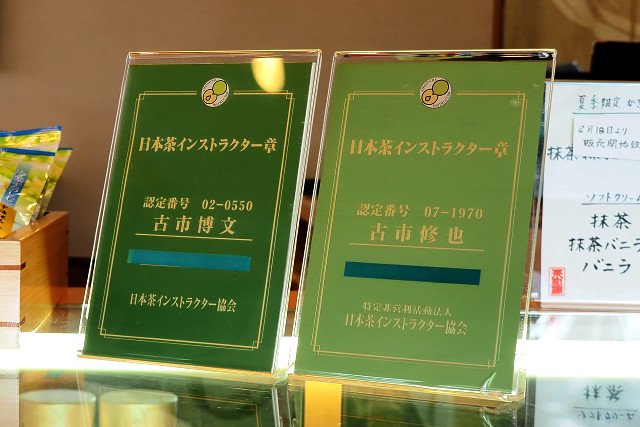

Our shop and cafe in Minami Kyushu City Sawaki opened in August 2018, with the aim of providing local Japanese tea enthusiasts with a unique experience, a feeling we call in Japanese ichigo ichie 一期一会. Among our staff, we have certified Japanese tea instructors and advisors, who will provide the best cupping for your pleasure.

Our shop and cafe in Minami Kyushu City Sawaki opened in August 2018, with the aim of providing local Japanese tea enthusiasts with a unique experience, a feeling we call in Japanese ichigo ichie 一期一会. Among our staff, we have certified Japanese tea instructors and advisors, who will provide the best cupping for your pleasure.

How we make amazing tea

Refinement

Using a air-based sifting machine, we sort leaf bits, powder, and stems from unfinished tea leaves.

Color sorting, Removal of unwanted items

Using a spectrometer, we further sort light-colored stems from the leaves, and remove any unwanted items from the leaf.

Green roasting for sweetness

Using a drum roaster, this process heats the leaves ever so slightly reducing moisture with infrared heat and bringing out a sweetness in the leaf.. Like a master coffee roaster, this process requires years of skill to carefully impart flavor without burning the green leaf.

Vacuum sealed, refrigerated storage

After green-roasting, we vacuum seal the tea in aluminum bags and move it into dedicated, long-term refrigerated storage to preserve quality year-round

Final quality check

To pack into retail bags, the leaves are removed from refrigerated storage and allowed to acclimate to room temperature before they are opened. Then prior to final packing, we do a last quality check by eye to ensure no unwanted particles remain.

Packing

Finally, we pack the tea into bags conducting a check by eye to ensure each bag has been properly sealed.

Quality assurance

Anti-insect film

Anti-insect film is laminated across our doors and windows to prevent insects from entering the facility. The film has a green tint bathing the factory appropriately in green (^^)v

Sanitation

We never place tea bags on the floor, always using plastic pallets to ensure that the tea is never at risk of becoming contaminated.